Dear Friends,

Very soon it will be Christmas, but first let us look back to see what has happened over the past few months. An important order has been delivered to the United States Armed Forces and we have also been fortunate enough to finally participate in exhibitions as well as to inaugurate our new factory. In general, we are getting a lot of requests and customers are truly beginning to recognise to what extent delivery time can be shortened and lifetime increased with VBN’s Vibenite® concept.

Delivery to US Armed Forces

VBN has delivered an important number of samples in three Vibenite® alloys for testing of the materials’ performance in several applications and setups. The main goal for the customer is to increase the lifetime of components and the uptime of their systems.

Inauguration of new premises

As we mentioned in the beginning of the summer, we now reside in premises three times larger than before which allows us to increase production capacity with future demand. New personnel has been employed and acquisitions of machines are planned. Given the current global situation, the inauguration had to be postponed until 10 November, when a large number of guests finally gathered to celebrate VBN’s expansion.

We are making cool parts!

During the Formnext exhibition, VBN was recognised by The cool parts show as one of the really interesting producers at Formnext. Take a look at the video showing a gear hob, explaining why 3D printing is a good solution for really hard materials!

Speaking of videos… our video “Worlds hardest steel” from 2017 now has reached more than 21,000 unique views! Make sure to watch it to learn more about what is to gain by 3D printing your components in Vibenite® !

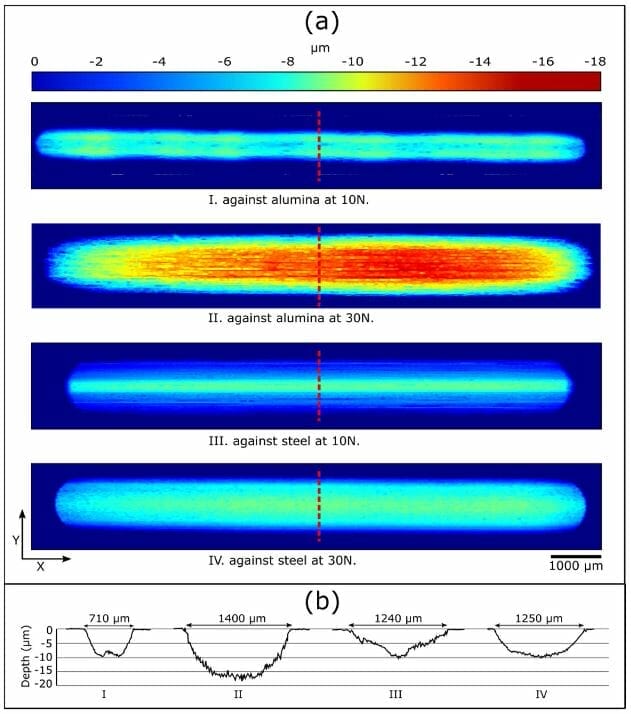

Vibenite® 480 in Wear Magazine

As you probably know, one of VBN’s materials is the hybrid carbide Vibenite® 480. The “dry sliding wear and friction performance” of this alloy was recently investigated by researchers at Manchester University, UK, National Physical Laboratory, Teddington, UK and Kocaeli University, Kocaeli, Turkey. Read more about the favourable results in the open-access article!

Merry Christmas to you all!