Materials

- VBN Components

- Materials

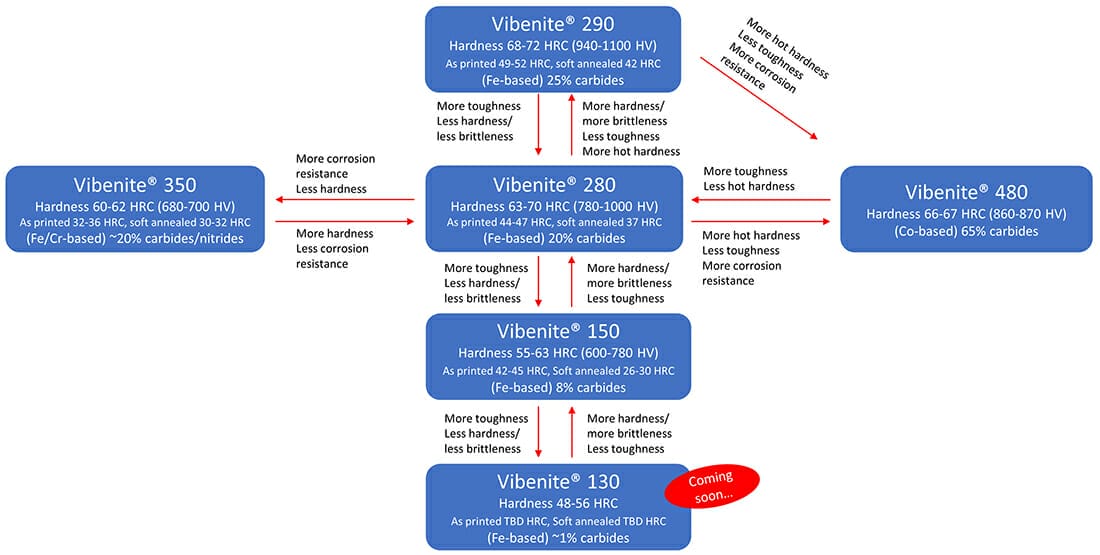

The Vibenite® materials

VBN Components has created a range of 3D printed, extremely hard, wear and heat resistant metals, to be used for components in demanding applications. We can produce your components in-house, according to your 3D CAD drawing, or provide you with a licence to produce in your own premises.

Benefits:

- Extreme hardness levels

- Excellent wear resistance

- No porosities and full hardness all the way through

- Uniform material microstructure, thanks to the AM-HSS™ process

- Very fast product development

- 3D printable

The Vibenite® materials share several benefits. Thanks to the additive manufacturing process, you have the chance to design complex geometries, combine several parts into one, add channels for media, reduce weight, or add other features to your component without any soft machining. You can also look forward to fast product development since your ideas can be easily implemented by simply creating a new 3D CAD drawing!

All Vibenite® materials are extremely wear resistant and hard due to the ultrafine and uniform microstructure. The hardness and toughness can be tailored by the heat-treating steps in individual ranges. The high performance combined with less unnecessary material use leads to long lifetime, high productivity, and cost savings.

Order our datasheets if you want to know more about each Vibenite® material. We will help you choose the optimal Vibenite® material for your component!

Vibenite® 150

A multi-purpose wear-resistant PM steel with a high level of toughness and fatigue resistance. It has a fine-grained Fe matrix and a hardness of approximately 58–66 HRC (600–850 HV). It works well for functional prototypes, parts difficult to machine, tool holders, cold work applications that place demands on both wear resistance and toughness, plastic materials processing tools and wear parts.

Vibenite® 280

Vibenite® 280 is an extremely wear and heat-resistant PM material, especially suitable for cutting applications such as gear hobs, broaches, shaper cutters and wear parts, or as a hard, heat-resistant substrate material for PVD coatings. The fine microstructure with high volume of fine, well-dispersed carbides results in a high toughness. Its hardness is in the range of approximately 63–72 HRC (780–1100 HV). It has proven to raise production capacity for industrial tools, for instance in engine production. Extreme erosive resistance has also been noted in customer applications.

Vibenite® 290

The hardest commercially-available steel type in the world: possible to harden up to approx. 76 HRC. Improve your existing HSS applications that need higher hot hardness or higher abrasion resistance. Vibenite® 290’s high Co content gives a very heat-resistant hard alloy, while its high quantity of carbide formers generates extreme levels of carbides. The result is outstanding wear resistance with an exceptional combination of toughness and hardness. The unique composition of Vibenite® 290 results in a material perfect for metal-cutting tool applications such as gear-cutting hobs, power-skiving cutters, shaper cutters and dry-cutting applications.

Vibenite® 350

This stainless PM steel is well suited to high-wear applications that need stainless properties, such as plastic processing tools (extrusions and injection tool parts, segments for segment screws), pumps and valve rings. Its high hardness of approximately 60 HRC (680–700 HV) and high chromium content provide good wear and corrosion properties and it is ideally suited to products such as pump impellers or valves, where there is a requirement for both complex shapes and high performance. These types of alloys are normally extremely difficult to machine. Read about the material’s exceptional wear resistsance in Nature Scientific Reports.

Vibenite® 480

Vibenite® 480 is a patented cemented carbide-type cobalt-chromium (CoCr) based alloy with very high levels of tungsten (W) and carbon (C). It is a new material-type with excellent hardness (67 or 70 HRC) all the way through and toughness, belonging to a group called hybrid carbides. The alloy has supreme wear resistance and hot hardness, thanks to the high carbide content. It is a very temperature-stable material, which means that no phase transformation occurs at high application temperatures. Vibenite® 480 is a good choice for applications where steel is normally used, but where replacing it with hardmetal would increase production efficiency, as well as towards hardmetal applications with complex geometry.

Please fill out the form to receive our datasheets

We do not share any received information with others.

Click the chart to enlarge.

The Vibenite® materials share several benefits. Thanks to the additive manufacturing process, you have the chance to design complex geometries, combine several parts into one, add channels for media, reduce weight, or add other features to your component without any soft machining. You can also look forward to fast product development since your ideas can be easily implemented by simply creating a new 3D CAD drawing!