Applications

- VBN Components

- Applications

Applications

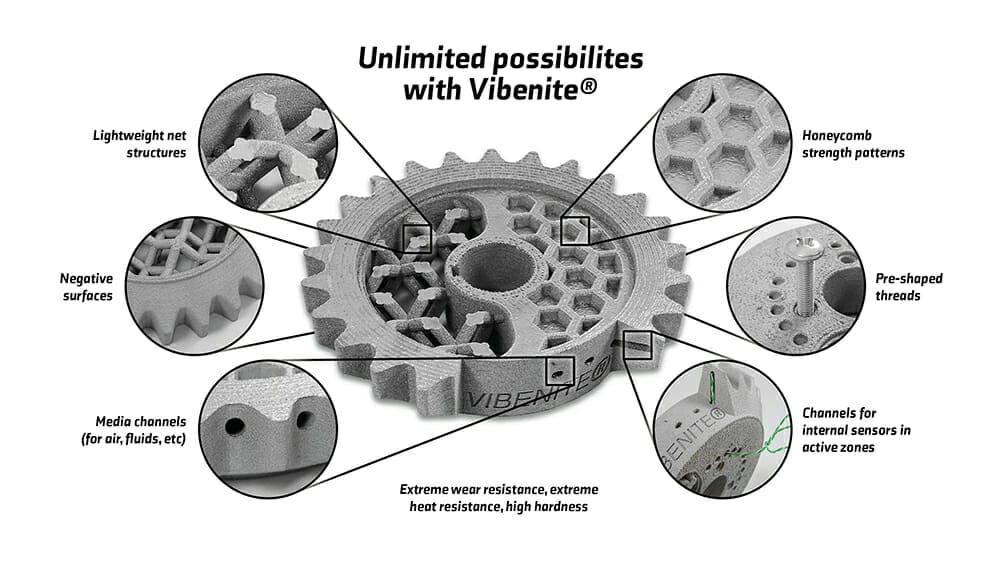

There are several areas of applications where additively manufactured Vibenite® components are suitable. The geometric freedom provides the possibility to produce complex shapes with increased performance and lighter weight. The reduced material waste and post machining steps combined with longer application lifetime and a lighter finished product, result in less energy consumption and environmental impact. Some examples of applications where Vibenite® will improve performance are listed below, but let your imagination guide you, the sky is not the limit! Contact us to discuss your specific application!